How “The Volt” Electrostatic Sprayer Works

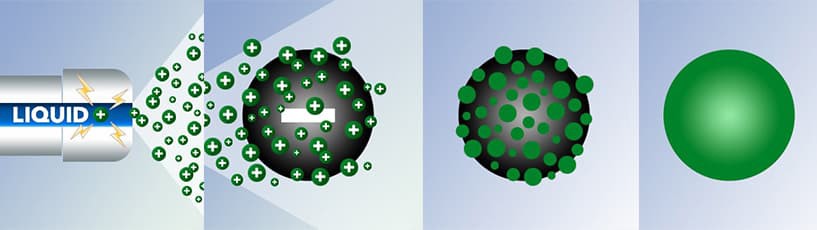

- Electrostatic sprayers work by applying a small electrical charge to aerosolized droplets when they pass through the nozzle, creating a positively charged particle.

- These charged droplets are attracted to surfaces, enabling them to adhere, or stick easily, even in dense cover.

- The electrostatic particles not only find and attach to surfaces more readily they also repel each other, providing complete and even coverage with each droplet being the same size.

- This results in less product being used and effective application with minimum overspray.

Electrostatic Sprayer Benefits

Since the charged droplets seek out surfaces, usually a single pass is sufficient to cover the area, saving time—especially for large spaces. In addition, this method of application uses less product, saving you money and preventing over-use, which can be harmful.

- Less Run-Off: Instead of your chemical dripping or running off the surface, it sticks to it better. This means you’re using less spray to cover more and run-off equals waste.

- Reduced Drift: Since the droplets are actually attracted to surfaces, more of the droplets find surfaces to stick to. In todays market, you need your chemicals to go where they are directed and your neighbors will be appreciative!

- Hard to Reach Areas: When chemicals are applied in typical manner, hard to reach areas are usually not covered as well and may be missed altogether. The charged spray will penetrate dense cover and cover both sides of the leaves but doesn’t stick to dead foliage.

- Enhanced Coverage: The charged particles are attracted to surfaces like a magnet, resulting in a wraparound effect. They can reach hidden or recessed areas that might be difficult to access with conventional spraying methods, ensuring more comprehensive coverage.

- Uniform Application: The electrostatic sprayer creates a fine mist of particles that are evenly distributed across surfaces. This helps to eliminate missed spots or uneven coverage, providing a consistent application of chemicals.

- Efficiency & Speed: Electrostatic spraying allows for a more efficient and faster application compared to manual spraying methods. The charged particles adhere quickly to surfaces, reducing the time required for thorough chemical application at higher field speeds.

- Reduced Chemical Usage: The electrostatic spraying process optimizes the use of chemicals or coatings, as the charged particles adhere to surfaces instead of being wasted in the air. Plus, the spray can be at higher concentrations and lower gallons per minute.This all will result in reduced chemical usage, making it a more cost-effective and environmentally friendly option.